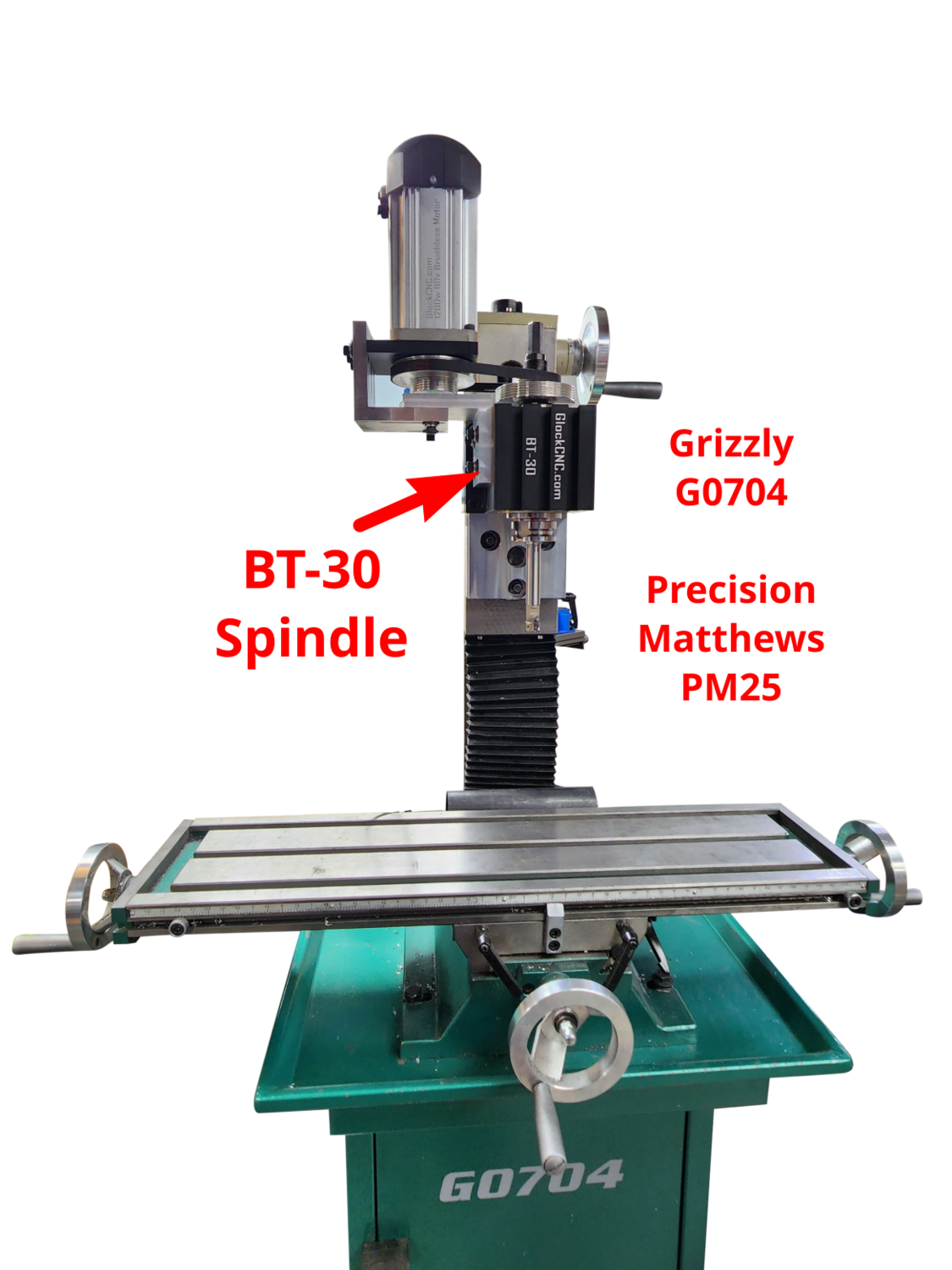

New BT30 Spindle Upgrade For Grizzly G0704 Mill

Seems like this has been a long time coming. For owners of the Grizzly G0704, Precision Matthews PM25, BF20, BF25 and…the list goes on, the spindle is a major downside. Let’s face it, the mill was made to fit a certain cost and that means some compromises. The bearings limit the speed, using a quill isn’t ideal for CNC applications, and R8 also isn’t ideal compared to other tapers. Benchtop machines would do better to switch over to BT30 or ISO30. Tooling has become inexpensive, easy to find, mega variety and super precise. In fact, tooling for a BT30 can be 5x or more accurate than average R8 collet. Yes, yes, I know Tormach has there TTS and it’s good if R8 is your only option…but, it’s not your only option now.

GlockCNC.com has recently introduced an adapter that allows there trusted BT30 ATC ready headstock to easily fit a G0704 or similar mill. It’s a direct bolt on upgrade. You can upgrade to their motors or fabricate a bracket to reuse the stock motor. Frankly, this would be the perfect time to upgrade your motor. The GlockCNC BT30 has an optional ribbed belt pulley…no more gears! Speaking of spinning up your spindle, you can get bearing options to support up to 25,000RPM.

Want to upgrade to an automatic tool changer or quick change pneumatic tool changer? Every GlockCNC BT30 spindle has the inside geometry for a petal clamp to be used. Just like you would stack some spring discs on the spindle top for an R8 conversion, you simply do the same for this. The petal clamp doesn’t come with the headstock, but they do sell it as an option. Initially, you might want to just stick with the threaded drawbar. You can use an impact wrench or impact driver to screw the drawbar in and out of the BT tooling. In this case, you simple use the threaded area where a pull stud normally goes in the tooling.

What are the downsides? GlockCNC sells out a lot. This means you’ll want to get your order in as soon as possible and be patient. It’s a one man operation at the moment. If you plan on using your current motor, you’ll need to do some drilling and tapping to reuse belt drive motor setups. This is no big deal, but just know that ahead of time. Also, if you get the deep groove bearings, you’re going to be at 8,000RPM max. You may want to upgrade to angular contact bearings.

Anyway, this is an excellent upgrade that’s been long overdue.

I suggest at checking it out https://glockcnc.com/store/#!/BT30-Headstock-For-PM25-BF20-or-G0704/p/502682728/category=140619003